NordicWoodJournal.com has recently visited the Valtra factory in Finland. We spent almost a week touring around in the country. The purpose was to check out some of the abundance of forestry machinery and technology that is being developed in Finland.

We have visited many of the Swedish companies over the past few years, but there are just as many if not more fascinating manufacturers in Finland, including some big brands. We started our journey at Valtra Oy in Suholahti just outside Äänekoski in the central parts of Finland. Here, most of the Valtra tractors are built, around 7000 every year.

France, followed by Germany, is Valtra’s biggest market. Finland comes in third place, where around 10 percent of the production is delivered. Sweden was surpassed by Norway last year, which is now Valtra’s fourth largest market worldwide.

The reason for the decline on the Swedish market in 2017 is, according to Valtra, that the delivery of popular models of the A-series became problematic as production in a Turkish factory was discontinued. The popular A3 was no longer being delivered at the start of 2017, and it wasn’t until the end of the year that the A4 could be delivered to customers in Sweden.

According to Valtra, the Swedish market differs from all other markets in that it has “two pikes” in terms of popular size ranges. In most countries, the average and greatest sales volume for tractors is around 150-170 kW, and they are popular in Sweden too. But in Sweden many smaller machines are also sold, and these often end up in forestry.

Two AGCO Factories in Finland

Emotions can be mixed when, as a Sweden, you visit the Finnish manufacturer that in 1979 took over and later discontinued the brand Volvo BM. In the lobby of the Valtra facility in Suolahti there’s – among some older Valmet models – an old Volvo T43 with a Hesselman engine, as a reminder of the Swedish legacy. Engine manufacturing was the origin of Valtra, commenced in 1949 and later expanded into tractor manufacturing in 1951. After many changes the Finnish state became the owner of the Valmet group which the tractors were a part of. The state began discontinuing their ownership in the 90’s and production was split up. The brand Valmet joined the paper machines and the tractors were named VALTRA (VALmet TRActors) in 2001. The forest machines, as we know, ended up with Japanese Komatsu and are manufactured in Sweden.

Since 2004 Valtra is owned by the American tractor group AGCO, who also own and manufacture Challenger, Fendt and Massey Fergusson. Other than the Valtra tractor factory AGCO also have an engine factory in Finland, AGCO Power in Nokia outside Tammerfors. Here, on top of engines for the Valtra tractors, engines for Komatsu forest machines as well as engines for various marine and industrial applications are produced.

It is easy to become nostalgic, but reality and the market today is looking quite different from what it was like in the heyday of Volvo BM, so Swedes should probably be proud of the fact that there is still tractor manufacturing in the Nordic countries at all. With deep roots in Nordic forestry, Valtra has a knowledge and understanding of the special needs that forestry presents. Something that is clear in some of Valtras technical solutions as well as in the adaptions and customization that can be made to the tractors straight in the factory.

Forestry Adaption in Serial Production direct in Valtra factory

Some of the Valtras forestry adaptions are made straight in the serial production. Tractors are built based on customer orders and all tractors are built on the same line regardless of model. It all starts with the transmission part, which is manufactured in the same factory in the building next door. Valtra offers several transmission solutions (which you can read more about in this thread: https://nordicwoodjournal.com/editorial/equipments/valtra-4-series-tractors-forest/), forest cabin, steel roof, protective plates, forest tires, larger hydraulic pumps, protective glass, Twin Trac/Quick Steer), and several other adaptions directly onto the serial production tractor. If one desires additional forestry focus and solutions beyond what is already offered, this can be achieved in the special department at the Valtra factory, named “Unlimited”.

Unique Forestry Adaptations in the Valtra Unlimited Department

Tractors are delivered here straight from the assembly line in order to be fitted with for example a rear view wedge, crane mount and crane. If one decides to go with a tractor with central lubrication this too is set up in the Unlimited department. Valtra’s offer of forestry adaptation is made possible in collaboration with Kesla who primarily deliver cranes and harvesting units. The Kesla system is well integrated with Valtra and the control panels of the tractors are fitted with Keslas Pro Control joysticks for the crane. Adaptions with crane and crane mount are not just made for the forest but similar constructions are also made for tractors within park & greenery care as well as farming.

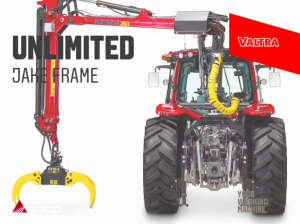

For crane mounting on the tractor, Valtra uses frames from Finnish Jake. If one wishes to make the tractor stand out, Unlimited can offer cool paint jobs. Prints that are applied with so called dipping technology are popular. When we visited the factory, the Unlimited department were putting a gold coat on a larger N-series tractor for a Finnish farmer. And there was a tractor to be delivered to Sweden which had a super cool version of “deep metallic orange”. According to Valtra, relatively few tractors for the Swedish forestry market pass through the Unlimited department. Most people are satisfied with the steel tank or make customizations in Sweden at local shops. Surprisingly many Norwegian tractors, however, do pass the Unlimited department. In Norway, “extra all” seems to be the way forward.

Here’s a video of the Valtra visit regarding parts of the forestry adaptions of the Unlimited department:

And some pictures: