Why are Valtra tractors so popular in forestry, and why has that always been the case? These are questions a lot of people may have asked themselves throughout the years.

Torbjörn and I visited the Valtra factory in Finland, and we now believe to have found the answer. Keep reading to see if you agree with our conclusion.

Hallsberg

As a Swede, you look for every piece of information that can make a connection to a Swedish historical perspective, and perhaps we have found just that in the Hallsberg cabin created by Volvo BM in the late 70’s. A smooth, flat floor and rotating seat. When Volvo BM discontinued as a brand in 1979, the cabin was something that Valmet, as they were called at the time, took with them. The cabin in combination with an ever-present Nordic focus on forestry is what we believe to be the reason why Valtra is what it is today. Hallsberg? It is a small town in the middle of Sweden, best known for it’s train station.

Valtra is special

Today, Valtra is part of the AGCO group along with Massey Ferguson and Fendt, among others. Here, too, the forest is a common thread. AGCO has chosen to divide their tractor brands in ways that minimize competing on the same markets. Fendt is meant to be a tractor with the latest technology, more of everything and with a focus on agriculture. Massey Ferguson is a volume tractor within agriculture. Valtra, on the other hand, aims at specialized solutions. For the forest (a relatively small tractor segment), for counties, airports, etc.

Twin-Trac

Valmet quickly took the Hallsberg cabin to new heights, and one of the greatest inventions is definitely Twin-Trac. Rotate the seat 180 degrees and you’ll find a steering wheel, direction selection, gas pedal, brake pedal, and gear. Pure genius. Twin-Trac has now existed for 30 years and around 10.000 tractors fitted with Twin-Trac have left the factory.

Valtra 6850HT Twin-Trac Turbine

I’m sure lots of foresters feel their mouths watering when reading the above headline. The Valtra 6000 series, which was discontinued in 2008, is a dream to many foresters, especially with Twin-Trac and turbine clutch.

But now times have changed, and while many still hunt for used Valtras online, Valtra are working hard to make their new models fill the void of the 6000 series.

Valtra N134A

As a unique model, the Valtra N134A is the model which has gained the most traction in the forest after the 6000 series. This is a tractor in the N-series (a middle model with the A-series being the smallest and the T and S-series being the largest), and within the N-series it’s a model at the larger end of the scale. The slightly larger N154E is the best-selling model, however this one has a greater spread in terms of transmission choice.

HiTech, Active, Versu and Direct

The various transmission options are part of the foundation of a Valtra. It’s important to gain an understanding of how the different options work, so let’s have a little run-down.

HiTech

Quite illogical is that HiTech is the lower end model you can choose. HiTech utilizes a five-step PowerShift transmission with four segments and an option of two gears. Fully utilized you would get 30 + 30 gears in the box (30 front, 30 back). Valtra calls their control of PowerShift “robot steering”. It’s a form of block located on the transmission unit which is operated by the computer in the tractor. Furthermore, there’s mechanical hydraulics and a fixed “Open-Center” gear pump of max 90 l/min for the work hydraulics. You can, however, get HiTech with turbine clutch, what Valtra calls Hi-Trol.

Active

Active also comes with PowerShift and mechanical hydraulics, but can also come with a cargo-aware hydraulic pump in three sizes, 115 (std), 160 and 200 l/min.

Versu

Versu, like HiTech and Active, has PowerShift, but also electronic steering of the hydraulics and an LS pump, like Active. Versu also comes with the new arm rest with touch screen, something Valtra calls SmartTouch. Through this you achieve an “almost hydrostat experience” even though it’s PowerShift. Versu is also unique (along with Direct) in its use of separate hydraulic oil for the transmission and work hydraulics.

Direct

Valtra’s bad boy in this case is named Direct and here they have skipped the PowerShift technology altogether. Instead, they use a hydrostat solution (CVT) along with an LS-pump for the work hydraulics, like in Active and Versu. Direct works like a modern harvester or forester, meaning that when you use the gas pedal the tractor will slowly start moving. The more you push it the faster it will go, and when releasing the gas pedal the tractor will stop and go into parking mode.

With Direct you also get a “hand gas” in the arm rest allowing you to skip the gas pedal and operate the tractor using your right hand.

As many may have realized already the Direct model is a perfect fit for the forest. You can crawl forward at full power just like a harvester or forwarder.

But as you may also have figured out already this achievement comes at a price. Direct is extra and as a customer you’ll have to decide if you think it’s worth the extra cost.

Most foresters will find that the hydrostat solution is not worth the additional cost and instead go with the Active model. The downside here is a somewhat rockier start and you’ll have to practice in order to get used to crawling in the forest. And you’ll never achieve the effect of Direct or even a Valtra with a turbine clutch.

This is actually our only objection to the Valtra strategy for the forest. If you can’t afford Direct, you’ll be compromising. This due to the fact that the turbine clutch only exists in the models that come with a gear pump for the work hydraulics and max 90 l/min, alternatively the Active or Versu solution with somewhat jerky starts.

Torbjörn and I tried out the different models at Valtra and other than the above we must admit that a great leap forward has been achieved with the transmissions – just speed up and go, even with PowerShift. We were also impressed by the visibility of the N-series. With the tractor window SkyView you have almost 7 square meters of windows in the cabin. Impressive. The only downside for those of us who are forest mad is that the engine of the rear windshield wiper is poorly placed when operating with a forest trailer and crane – it blocks some of the visibility. Valtra didn’t know about this themselves, but in Sweden some tractors of the N-series have been remodeled and the engine has been placed at the bottom of the windshield instead. I will be visiting one of these tractors in due time and provide a report!

Hill-Hold and inhouse development

To make HiTech, Active and Versu even more attractive there’s an add-on called HillHold. It’s not as smooth as Direct, but with relative ease and without the need to pull any hand break you can get the tractor to stop regardless if going uphill, downhill or on a flat surface.

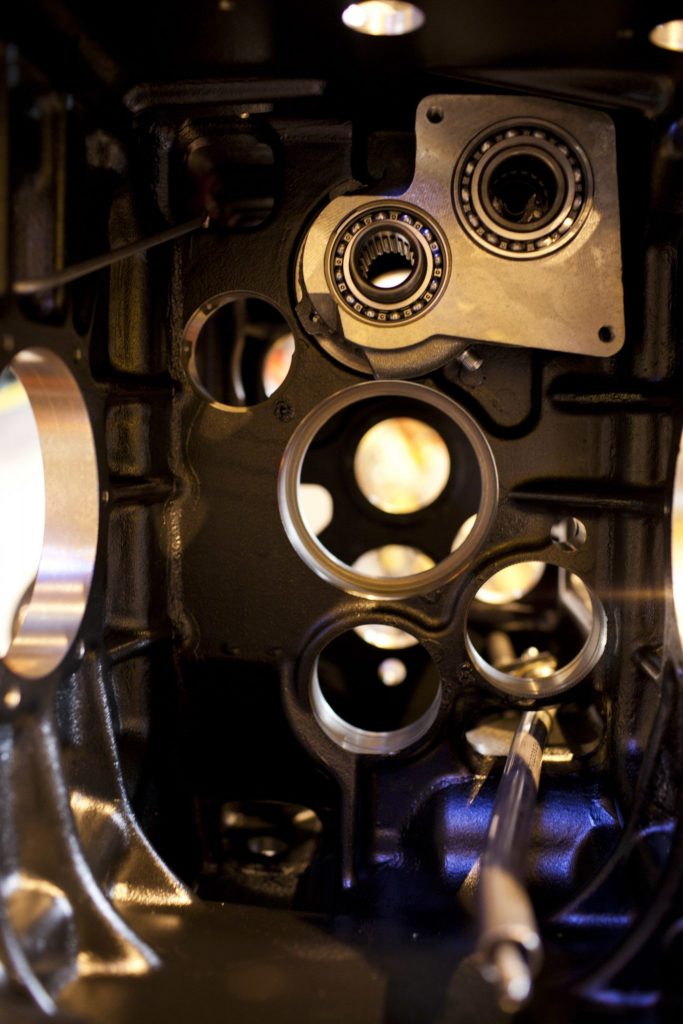

Valtra produce all their transmission solutions by themselves in their own factory inside the Valtra area. A quite impressive process which begins with a molded shell and ends with a complete transmission unit. Unfortunately, we were not allowed to take any pictures from inside the factory.

Nimble despite growing pains

Tractors in general tend to grow bigger. In 10 years the engines have, on average, turned 30 hp bigger and among the mid-sized models 38” wheels are dominating.

Valtra must be given credit though for continuing to produce relatively short tractors with a narrow turning radius, and the optional QuickSteer (also available for Twin-Trac) is a great feature. QuickSteer is just as it sounds. You can turn the front wheels almost twice as fast when the feature is turned on. QuickSteer works at speeds up to 20 km/h and should be invaluable in the forest and at the farm with a front loader.

Something out of their hands, though, is that the tractors tend to become wider. Compare the Valtra 6350 HiTech from 2007 with a Valtra N134A from 2018 and you’ll find that the latter is 28 cm wider. Valtra 6350 is 2.27 meters wide, while the N134 is 2.55 meters wide. The weight has also increased by 1 ton.

The above can have a marginal impact on potential forestry customers, however we mustn’t forget that those who don’t fancy the larger N-series can still fall back on the A4-series, which now in its most recent form also has a larger cabin with a flat floor and of course the rotating seat.

Steel tank = Sweden

We’re somewhat surprised when we look at an overview of how the Valtra tractors forestry adaptions differ between countries – Swedish forestry customers want a steel tank for their forestry adapted Valtra. In Finland, in comparison, the original plastic tank along with plates covering the entire undercarriage of the tractor is much more popular.

The question is, why is this?

The steel tank is more expensive and can hold a lot less diesel, and the plated undercarriage covers the entire tank area and even parts of the sides. Is this something we should reconsider?

Forestry Tires

The ground clearance of the Valtra N-series is quite hard to beat – a whopping 55 cm, and the plates covering the undercarriage, which are mounted in the factory, are now so well made that they don’t affect the ground clearance negatively at all. Since many Valtras end up in the forest they have also produced special rear mud guards which are narrower, and all black, thin plastic has been removed. In other words, there’s no risk that they get stuck when branches come along for the ride while chains are mounted.

When ordering a new Valtra you also have the option to choose tires based on what the tractor is to be used for. In the forest, Forest Rider and King Forest tires dominate. But the most popular option is the MultiPlus tire which is a hybrid tire for use in the forest, in agriculture, and on the road.

Conclusion

It has been a very rewarding experience to learn more about Valtra and their tractors, and I hope that this text has taught you a thing or two.

Something we mustn’t forget despite the tractors in general having grown larger is that they all come with SCR/AdBlue technology in the diesel engine. This is a sign that the new technology has more or less forced the engine manufacturers to do magic – the diesel consumption actually seems to have reduced despite an increase in horse powers, which is impressive.

Something I personally liked was also the two “E” models of the N-series, the N114E and N154E. These are optimized to work with reduced speed and fuel consumption had been reduced by up to 10%.