The bark-beetle has no boundaries, everybody affected can agree to that. The bark-beetle invaded Europe during 2018 and 2019 and forestry people around Europe are still struggling to get the damaged wood, and the bark-beetle, out of the forest as quickly as possible. Mainly CTL logging equipment is used, but father and son Klinkenberg in Belgium have chosen another type of machine system.

Efficient bark-beetle hunter

We are talking about a John Deere machine with which the right operator can reach very high productivity. A normal tree is cut in approximately one second.

The first eye-catcher on the visited site is the extremely low stumps. The operator, Anton Klinkenberg junior, puts the felling head deep on to the ground and cuts low. This is possible thanks to that the buttresses are cut beforehand with a chain saw. The low stumps bring more wood out of the forest. It also makes it easier for the following machines, skidders, harvesters and forwarders.

Unconventional methods

Anton Klinkenberg is known for using unconventional methods. His son, Anton junior, follows his father’s footsteps and now father and son are working with a machine that is very unusual in Europe. This machine might even be one of its kind in Europe. The method itself, to fell and bundle whole trees, is quite unique for Europe. The whole-tree bundles are either skidded to a landing or delimbed and cut to lengths on-site by a harvester.

The system offers many possibilities, of which Klinkenberg not yet have tried all in the hunt for the bark-beetle.

Safe felling

One major reason for choosing this system was health and safety for the people working in the forest. Felling operations of big trees often cause accidents, something that Klinkenberg wants to avoid.

One manual forest worker is however included in this working chain. He removes the buttresses from the standing trees, so he doesn´t fell any trees. After that is done, Klinkenberg junior can cut the trees very close to the ground.

The machine

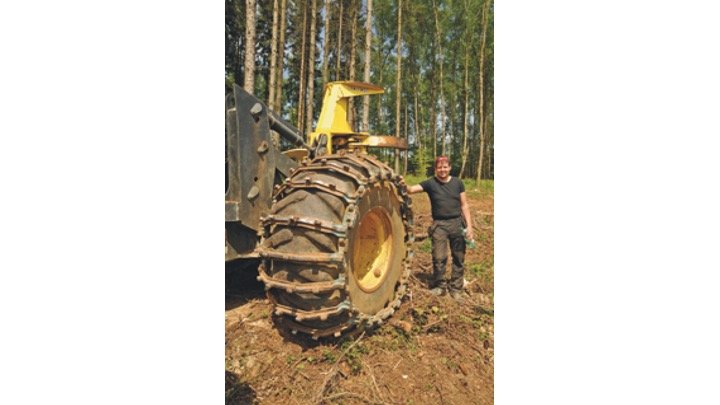

The machine is a John Deere 843K direct drive. A quick look may tell you it´s a skidder, but at the front, a John Deere FD22B felling head has been mounted. The FD22B has a maximum felling diameter of 55 centimeters. The diameter of the 18-teethed blade is 142 centimeters and the head opens 130 centimeters. The height of the head is 3 meters and the weight 3 metric tons. The felling head is equipped with an accumulation function that makes it possible to take more than one tree at a time, as long as the trees are not too thick.

To make the machine stable, Klinkenberg has made the John Deere 30 centimeters wider. 15 cm on each side. This was made by prolonging both wheel axles on each side with 15 cm thick steel plates between the wheel and the hub.

The wheels on the front axle, are equipped with 900 kg tracks to increase the stability even more.

Sturdy teeth

As mentioned above the trees are cut very close to the ground which gives a tidy impression of the site. The stumps are almost invisible. Nevertheless, the 18 replaceable teeth on the saw blade last up to 30 000 cubic meters felling. This is thanks to that they can be turned 90 degrees three times. When all sides of the teeth have been worn out, they have to be replaced by new ones.

There are different price levels for teeth where the cheap ones cost about half of the expensive ones. It´s all about steel quality and how long they last. Klinkenberg recommends the expensive ones as they last longer and keeps the sharpness so that also somewhat worn teeth could cut a normal stem in about a second. The cheap teeth wear out faster and are more sensitive to heat.

Working cycle

The tree is cut and held vertical by the John Deere while the operator moves the machine to the next tree to cut. After the cutting, the trees are laid down in bundles. The tilting function in the felling head is strong enough to offer centimeter precision when the trees are put on the ground, in the right direction for the next operation – harvesting or skidding.

Thanks to the prolonged wheel axles and the heavy tracks Klinkenberg can work smoothly with the machine in the terrain. He can easily carry one or two trees standing up, also when crossing small obstacles like stumps and stones, without risking rolling over with the machine.

Summary

Safety, efficiency, precision, clean work and good planning are keywords that Klinkenberg junior and senior holds important in the battle against the bark-beetle or any other calamities in the forest.

Efficiency lies not only in one single machine but in the system the machine is a part of. Low stumps and tidy bundles that are placed in the right direction for the next machine are examples of this kind of system thinking.

As for safety, a minimum of staff working outside the machines minimizes the risks for injury and death among the staff.

Fast and efficient. In just a few moments there are no bark-beetle infected trees in sight anymore. For how long nobody knows. But if there will be another bark-beetle attack in Belgium, the Klinkenbergs will be ready for a quick response.

Text: Dieter Biernath und Per Jonsson

Photos: Biernath und Klinkenberg

In cooperation with Forstmachinen Profi, Forstfachverlag GmbH