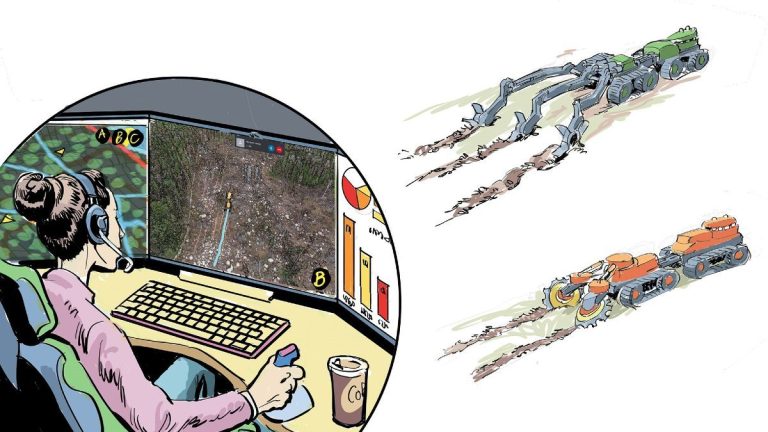

The Forestry Research Institute of Sweden, “Skogforsk”, has received funding to develop a remote-controlled scarifier. The goal is to bring the technology of remote-controlled forest machines closer to reality.

Illustration: Skogforsk.se

A remote-controlled scarifier is being developed

The choice of a scarifier for this project is because it’s easier to control compared to other types of forest machines. Scarifiers operate in an environment where most trees have been removed which makes communication between the machine and a remotely placed operator much easier. The interaction with the machine is also less intensive as no crane is being used during operation.

Furthermore, a scarifier normally offers an inconvenient working environment for the operator as vibrations are worse than in a forwarder or a harvester. This is because the scarifier operator must operate in straight lines and cannot avoid obstacles in the same way as with e.g., a forwarder.

“A scarifier must cover the whole site, also difficult terrain,” Martin Englund at Skogforsk explains. “If the operator instead can control the machine remotely it should be a great improvement of the working environment for the operator. In the long run, it could also mean that simpler and cheaper machines could be used as there will be no need for advanced systems for e.g., cab-damping,” he concludes.

Photo: Per Jonsson

The project covers many areas

The project includes several knowledge and development areas where progress contributes to making remote-controlled scarifying possible. Among other things, relay stations will be developed and evaluated for improved coverage of radio communication. Different operator support systems will also be looked at to cover the operator’s need for information.

Another part of the project is to find out how driving in the terrain is affected by remote-controlling and if, and how, a digital planning tool could be helpful in route planning. The study, which starts now and ends in 2024, will end with a demonstration where the machine will be controlled by an operator from an operator’s cabin close to the working site.

Remote-controlled machines

Sometimes I think it’s a pity that the forestry machine business is so small. Compared to construction machinery or trucks, the volumes that we are talking about in forest machines are ridiculously small. This means that the incentive to invest in development is smaller compared to other types of vehicles. E.g., self-driving trucks have been underway for a long time now.

As for forestry machines, we have seen machines like the remote-controlled ERJO-chipper and the Beast & the Courier, both machine systems that actually work. And then of course the ongoing projects with the Autoplant and the autonomous machine concept. Not to mention the AirForestry project which is both remote-controlled and very exciting.

I have mentioned it before, and I still believe that the technology is there. It’s the money that’s missing. I mean, “we” can send a vehicle to Mars and drive it there, remote-controlled from the Earth, so …

What´s positive is that there seem to be many projects going on simultaneously for the moment, which hopefully means that something will come out of it soon.

It’s about time that the forest machine business takes the next “giant step” in its development. We have been waiting since the 80s for that.