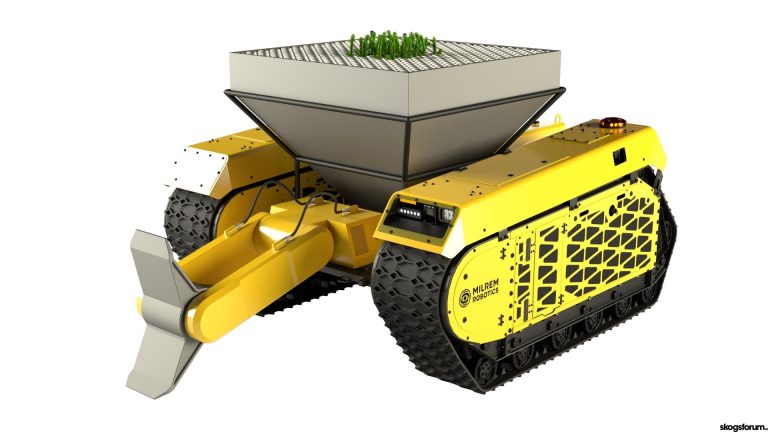

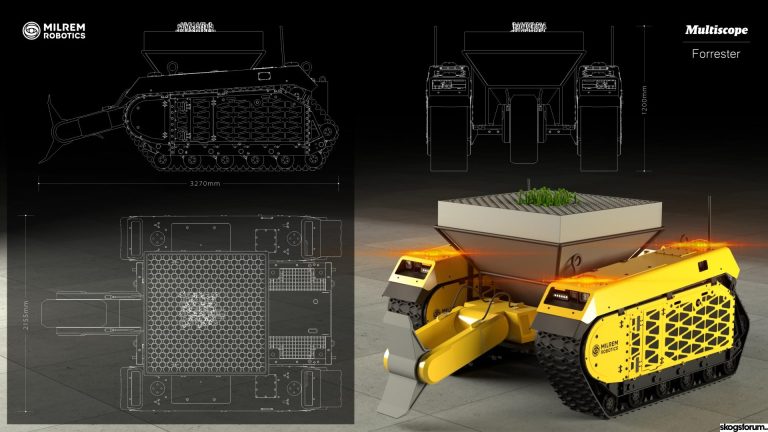

It becomes more and more obvious that planting by hand is slowly becoming too expensive. One sign of that is that it turns up new ideas on how to plant with machines every now and then. The latest (as far as I know), is the “Robotic Forester” developed by the Estonian company Milrem Robotics who manufactures different types of UGV’s (Unmanned Ground Vehicles) for military and civilian use.

Source: Priit Vellak, Milrem Robotics

New planter

A while ago we wrote about a Swedish autonomous planting machine called Autoplant. The plan in Estonia, is to develop an planting machine that is based on an already existing military autonomous base unit from Milrem Robotics’ range. The project is in cooperation with Estonian University of Life Sciences in Tartuu and the Estonian State Forest (RMK). A “secret” Finnish company, who is specialized in scarifying and mechanized planting, is also partner in the project.

The Civilian Development Manager at Milrem Robotics, Priit Vellak, is a forester and responsible for this project. He is also working on a doctoral dissertation on autonomous planting machines based on Milrem Robotics technology.

Small machine with low ground pressure

The UGV that will be used as base unit is a proven machine that has been sold in 10 countries. It´s an unmanned machine with rubber tracks. The driveline is an electro-diesel hybrid, but it can also be converted for fuel cell use (hydrogen).

The first step was to adapt the base unit for forestry use. The clearance height was increased to 80 centimeters (31”) and the width was decreased to 170 centimeters (67”). The length is only 240 centimeters (94”). The weight of the base unit without the planting equipment is 1,6 metric tons. According to Priit Vellak, the tracks on the machine make the ground pressure correspond to a third of a footprint which means that the machine can be used also on very soft soils.

Sensor system

The machine can use data from satellites or drones as base for the work planning. The machine will also be equipped with its own sensor system. Milrem Robotics have developed a sensor-based control system that will be used for route planning, controlling the machine, avoiding obstacles, guarantee safety and to find suitable planting spots.

“We have developed a sensor kit for our autonomy and the algorithms called “MIFK”. This is a complete set of functionalities including waypoint navigation, obstacle detection ans avoidance and safety.” says Priit Vellak.

Lower reforestation costs

Together these systems will make the machine completely self-driving. The target is that the machine shall be able to plant twice as much as a manual planter. Calculations made together with Estonian State Forest shows that the reforestation cost can be reduced by 16 % based on Estonian conditions. According to Priit Vellak, the streamlining in e.g., Sweden and Finland will be even better.

The machine should carry 300 plants and should be able to scarify and plant one hectare in 5 – 6 hours. The scarification will be either spots or mounds of 0,2 – 0,3 m3 size and a height of 0 – 30 cm (0” – 12”) depending on type of soil.

Source: Priit Vellak, Milrem Robotics

Looking for cooperation

For the moment the base unit is being prepared. Next step will be to assemble the scarifying and planting equipment. The company calculates that the machine will be ready for testing in the autumn. We will keep an eye on that.

Milrem Robotics have no connection to forestry and no real interest in building forest machinery. Instead, they seek cooperation with companies in the forestry business. They would prefer one of the major brands like Ponsse, Komatsu Forest or John Deere Forestry. The machine is designed to operate in temperate boreal forests, initially Sweden and Finland. The ambition is that it should be used in all countries with similar forests.

Source: Priit Vellak, Milrem Robotics

Here is a film of one of the first tests in the forest:

and some more information here

Yet another planting machine

There have been many attempts to mechanize forest planting, but few have succeeded. Closest to success has been the Silva Nova project in the 80’s and 90’s. A project that is awoken again under a new name, the PlantmaX. The most commercially successful planting machine is probably the Bracke P11 planter that entered the market in the early 90’s and was adapted to south American conditions around 2010-11, then named the P12. Bracke Forest also delivers the planting heads for the Komatsu D61EM planter in Brazil.

The Finnish manufacturer Risutec also have a range of planters, quite similar to the Bracke P11.

Why haven´t any planting machines broken through?

Well, one reason is that the forest terrain is not like a field. Stone, stumps, soft soil, hard soil, peat, slopes, slash, etc. has to be handled somehow. The plant itself is a sensitive, living thing that has to have the right care to survive in its new environment and through the whole logistic chain until it reaches its planting spot. To handle such a fragile thing like a plant with a (often) huge machine, is a difficult combination. In the meantime, the machine has to be quite sturdy to cope with the above-mentioned obstacles in the terrain.

Another problem with mechanized planting is the logistics; How do we get the plants to the machine, and then into the machine? On all planting machines available today, the plant feeding/loading has to be done more or less by hand. Also here you have to take into consideration that the plants are fragile and has to be handled with care.

The other main reason why the planters haven´t taken off, is the cheap labor from abroad. That the forest industry started to look at mechanized planting in the first place, was because the manual planters were becoming too expensive. So, a replacement was needed. But before the planting machines were ready for the market, north western Europe was “invaded” by cheap and willing labor from the east as the Iron Curtain fell. Suddenly the problem with expensive planting was solved and the machines were not needed anymore.

Back where we started

Now we are back where we were 30 years ago. Also the foreign manual planters are becoming expensive, the locals (Swedes, Finns, Germans, etc.) have forgotten how to plant or have probably become too lazy to do it, or won’t do it for the prices that are offered. The Covid-19 pandemic made it difficult to bring people across the borders which made it even more complicated and showed us how vulnerable we are. Suddenly we need the machines again.

But where are they?! Most machines available today are more or less prototypes. Some actually runs quite well, but only under special conditions, such as on fields or field like forest ground. Novelquip, TT Plant, and FPM, are examples of machines that actually exist and work – on some soils. These are just a few examples, there are more, there is no lack of planting machines. The problem is to find one that functions efficiently under all, or most kinds of conditions.

It will for sure be exciting to see the next one …