Here at NordicWoodJournal.com, we write a lot about CTL machines. It´s logical as we are situated in Sweden where close to 100 percent of the felling is made by CTL systems. It´s also here in Sweden, and in Finland, most of the CTL machines are manufactured. But what is so good about the Cut-To-Length method that full tree handling never broke through here?

What is CTL?

CTL, or Cut-To-Length, is based on a two-part logging system where one part, a harvester, or a chainsaw operator, fells the trees, delimb them, and cut them into lengths (logs) at the stump in the forest. The other part is a forwarder that brings the logs to a landing at roadside where the timber is piled up in different assortments.

Full-tree handling

The opposite, full-tree, or tree length handling is a system where the trees are felled by chainsaw or a feller buncher and brought to a landing by skidder or cable line. In some cases, delimbing is done at the stump and the stems are brought to the landing. The alternative is that the whole trees are brought to the landing to be delimbed there. Bucking is done either at the landing or at the industry.

Photo: Deere.com

Illustration: Deere.com

Why Cut-To-Length?

The preferred method in an increasing number of countries, is the CTL method. As mentioned above, CTL represents almost 100 percent of the felling operations in the Nordic countries. Today, 66 percent of the World´s felling is done by CTL systems according to The Perfect Cut by Ponsse (2020). The corresponding figure for 2011 was 35 percent, an almost 100 percent increase in less than a decade. Here follows some explanations to why the popularity of the CTL method is growing so strong.

The CTL method is environment friendly as the wood could be forwarded to a landing with very little soil disturbance compared to full-tree handling where the trees or stems are skidded (dragged) to the landing. To carry logs, instead of dragging stems, on a forwarder also means that there will be less damage on standing trees and their roots.

As the trees are processed in the forest with a processor, needles, tops, and branches are left which help to enrich the soil and promote regeneration. The processor/harvester can use branches to create a mat for the machines to drive on to protect the soil and the roots. By doing that, the timber can be brought out from the forest with few or no tracks after the felling operation.

Photo: Per Jonsson

As mentioned above, the CTL method is based on two parts: One part that fells, delimbs, and bucks. This part is normally a harvester but could of course also be a logger with a chainsaw. The other part is the forwarder that brings the timber to the landing. So, the job is normally done by two machines.

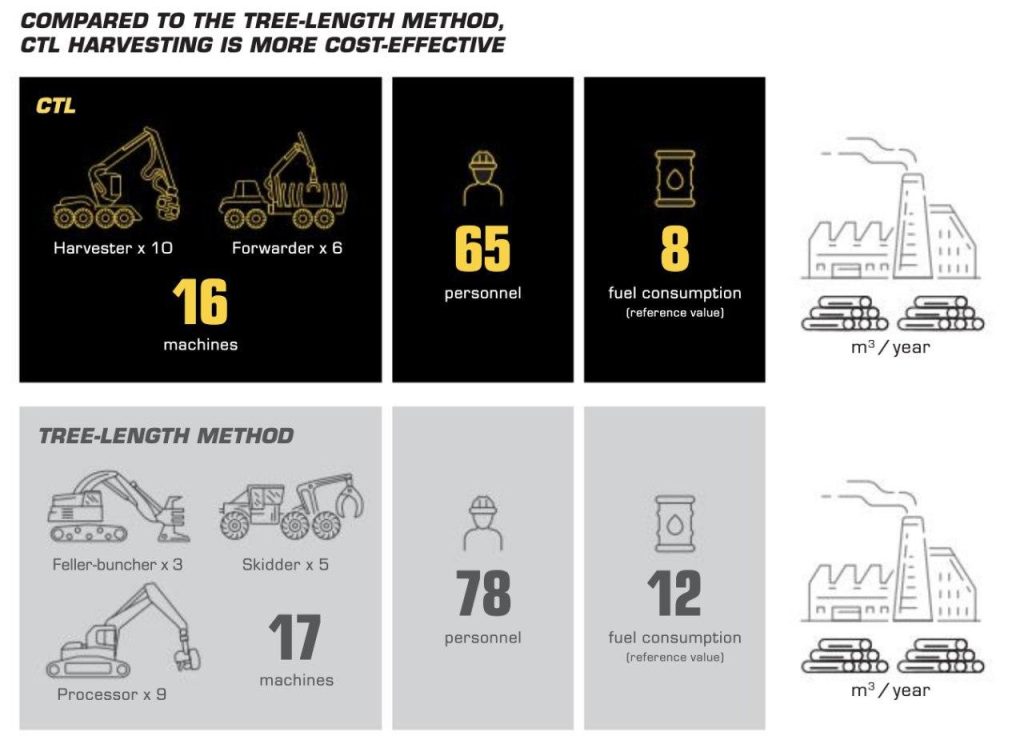

This should be compared to full-tree handling where normally three or four machines do the same job: A feller buncher, a skidder, a processor, and in some cases a loader to stack the timber. Ponsse has illustrated this like this:

Illustration: Ponsse.com

In total the CTL method is more efficient as its two-machine team can perform tasks that require three or four machines with the full-tree system.

Downsides with CTL

Are there any downsides at all with CTL system?

Well, as the CTL machines are quite advanced machines technologically, they are expensive meaning that the up-front cost for the system is higher than a corresponding full-tree setup. As the CTL machines are advanced, they also require educated operators which could be an obstacle in some cases.

Some sawmills want the whole stems in their yard to decide the lengths themselves according to requirements from their customers. In this case, the full tree system is more flexible.

One limitation with the CTL machines, especially the harvesters, is the size of the trees. The harvesters can only fell trees up to a certain diameter. Also, thick branches can be difficult for a modern harvester to handle. If there are only a few single “problematic” trees on a site, it´s common that a chainsaw logger is hired to take care of those. But if a whole stand is like that, other methods should be chosen.

Steep terrain could be a problem for CTL machines. But here solutions have turned up. E.g., sturdy winches that the machines could be equipped with. Winches that hold the machine in the slopes and make it possible for them to go both up- and downhill in a controlled manner.

Conclusion

The development of the market for CTL technology during the last two decades speaks for itself – CTL is in most cases the most cost-efficient and environmental friendly method to bring out timber from the forest.

The CTL system doesn´t necessarily mean that the harvester must fell all trees in a felling operation. If there are valuable, thick trees on site, these could still be felled and, the most valuable logs, bucked by chainsaw. When that is done, the processor/harvester processes the rest of the tree, and the forwarder brings it all to the landing.

In countries like Sweden and Finland where the CTL system has been ruling for decades, it´s obvious that the forest management adapts to the machine system. That´s one of the reasons that we hardly have any thick forest left here. Such a development makes more and more forests suitable for the CTL system. It could however be discussed if that is good or bad. The environmentalists probably have a slightly different view of it than the forest companies.

More information

Here you will find the above-mentioned “The Perfect Cut” by Ponsse.

Here is Wikipedias description of CTL.