CTL, Cut-to-length, has been the dominating method of logging in the Nordic countries for over 50 years. The rest of the World has been hesitating, sticking to the good old full tree system, but times they are changing. CTL Machine manufacturer Ponsse from Finland did a great compilation of the benefits of CTL. Here is a brief summary.

CTL – the future has arrived

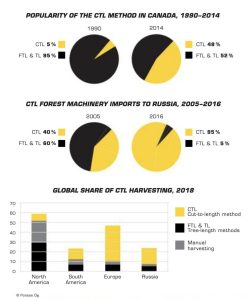

Today 66 % of all mechanical timber harvesting in the World is done by CTL machines, according to Ponsse. Within Europe, over 70 % of the timber harvesting, both manual and mechanical, is done with the CTL method. As good as all new timber harvesting projects in the World are now based on CTL solutions.

How can that be?

Only 20 – 30 years ago CTL was almost unknown in large parts of the World. In 1990 only 5 % of the timber harvest was done with CTL. In 2014 the figure was 48 %.

How come that “the Nordic method” has become the dominating method in most parts of the globe? Let us try to explore that, with a little help from Ponsse.

Efficiency by CTL

As the name of the method suggests, the trees are cut to lengths already in the terrain. The operator of the harvester, with some help from a computer, decides the lengths and he also decides which log goes where. (We wrote about this at NordicWoodJournal.com a while ago in the article Swedish Forestry #6 ). He puts the different assortments in piles for the forwarder to pick up. Spruce pulpwood for the spruce pulp mill. Pinewood for that mill. Sawlogs for probably at least two different sawmills, and so on if there are more assortments involved.

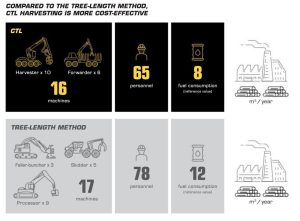

The forwarder piles it up in the same way at the roadside for the trucks to pick up and bring directly from the forest to the right mill. No landings or terminals in-between are needed. This gives a minimum of personnel involved and with fewer machines, less fuel is needed which is good for the environment.

Environmental issues

As for the environment, as the trees are delimbed and cut in the terrain, the brush stays there and give the soil a healthy dose of calcium and nutrients from the bark and the branches in the slash. Also, the harvester operator puts the brush out in front of the machine as a ground cover to avoid deep tracks in the soil and to protect the roots of standing trees.

11 reasons for CTL according to Ponsse

- Ready to use – Timber is bucked into grades logs in the terrain according to their intended use. This allows a high-value yield and an efficient logistic chain.

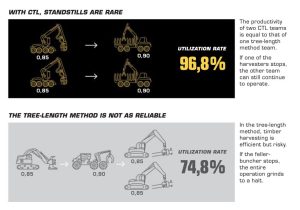

- Practical and balanced – Allows for more even and reliable harvesting operations.

- Working all year round – The same machines could be used in different kinds of harvesting, from first thinning to regeneration felling.

- From forest roadside to mill – Not only the harvesting and forwarding are cost-efficient. Further savings are achieved through the whole logistic chain from the roadside to the mill.

- Cut to order – The CTL harvester optimizes each trunk based on the specifications in the client’s order and bucks the trunk into these predetermined lengths.

- Careful cutting reduces waste – The CTL harvester’s thin chain cuts each trunk precisely, with minimal damage to the tree.

- Sustainable continuous cover forestry – Made possible by CTL thanks to the flexible harvesting method.

- Agile CTL machinery copes with slope – CTL machines have low surface pressure and is well balanced in an optimal way. This makes the machines suitable for harvesting in soft peat slopes.

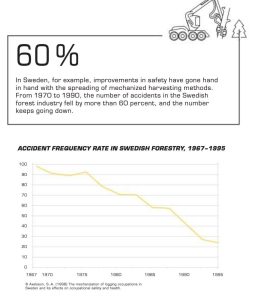

- Efficient, safe and mechanized – Manual harvesting in steep terrain is extremely dangerous. Under such conditions, mechanized harvesting saves lives.

Mechanized harvesting is safer than manual. - Securing uptime – When work is well planned, a CTL machine team drives down costs on all fronts.

- Better for the environment – The risk of fire is lower in a well-managed forest. You get fewer transports as the logs go directly from the roadside to its final destination. Brush is left on-site as fertilizer, meaning that no, or less, fertilizers are needed.

The perfect cut

The bullet list above shows some of the benefits of CTL according to Ponsse. You can read more about this, and much more, in the Ponsse-folder The Perfect Cut here.

Source: Ponsse folder The Perfect Cut

Photos and illustrations: Ponsse.com