We have written about both forestry machines, forest owners and wood buyers. But how does the timber come from the forest to the industry? We visited Christer Karlssons Åkeri in south Sweden to have a look at a part of the logistics around timber transports.

Timber trucking company

Christer runs a company with six timber trucks, one Volvo and five Scania. He works for Swedish state forest Sveaskog and he has one employed driver for each truck. He also has a modern workshop and an office in the same building.

Choice of truck brand

Discussions about what brand that´s the best is always going on everywhere, I guess. The Volvo in his fleet is the top of the line with 750 hp. It used to be Christer’s favorite and he had more Volvo trucks before, but the fuel economy has made him change his mind. The Scania 650’s that he also has, are more fuel-efficient and cheaper to drive, according to Christer.

Timber logistics

Sveaskog, who Christer works for, have few own industries in the area where he is operating. That means that the wood that is harvested in the state forest is sold to different saw- and pulp mills.

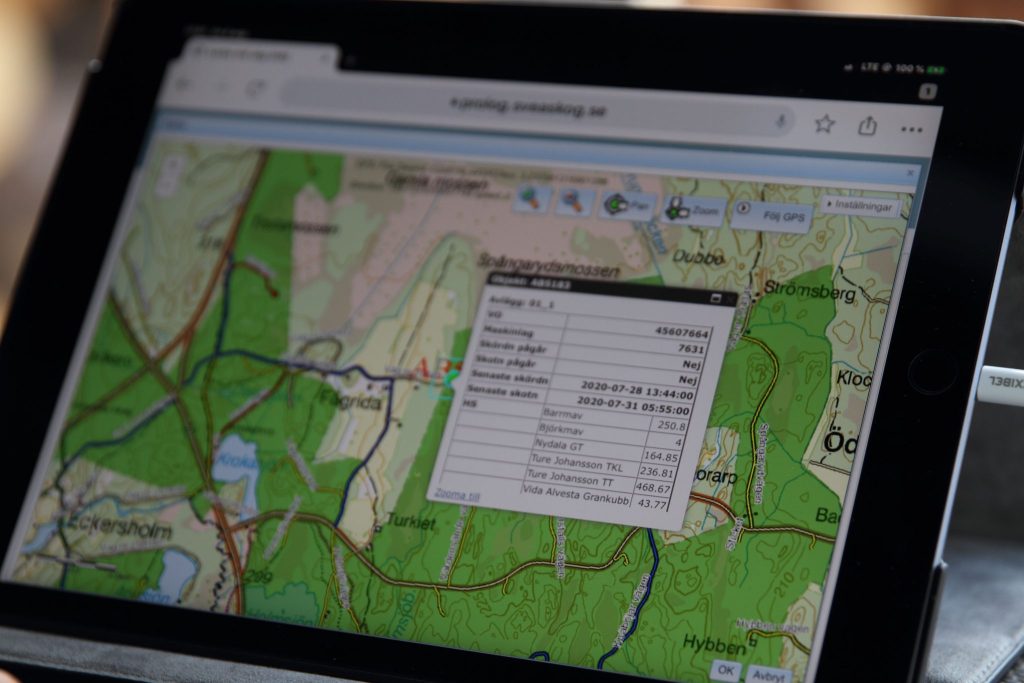

For the drivers to be able to sort out what goes where, and from where, they are connected to the Internet all the time. Every landing in the forest has a number and is shown on a map that Christer and the other drivers can see in their computers in the trucks. A red dot shows the landing on the map. When clicking a dot, they receive information about what is stored at that particular landing, and where to the different assortments shall be delivered.

Before the driver departs from a landing, toward the mill, he or she reports over the Internet that a load is underway. A similar report is made after unloading as well.

Measuring the wood

Measurement is a bit different for pulpwood and saw logs. Normally, in south Sweden where Christer operates, pulpwood is measured in the stacks on the truck before unloading. The sawlogs are measured one by one at the sawmill. There are, however, differences in methods within Sweden, not to mention within Europe.

Almost all wood that comes from the Swedish forest is measured by a wood measuring association, Biometria. Their staff are located at the mills around the whole country. All results of the measuring go through Biometria’s system and regulates volumes and qualities for payments for both wood and work. Biometria sends the results to everybody involved – buyer, seller, contractors, etc.

Measuring sawlogs

At the sawmill all logs are piled up and sorted by seller and contractors. When a particular timber portion is to be measured, it´s brought to a measuring station. A conveyor brings the logs one by one through the station where they are measured automatically. The quality of each log is determined manually by a scaler in the station. Finally, the logs are sorted according to the sawmill’s requirements.

Measuring pulpwood

The pulpwood is measured on arrival at the pulp mill or terminal, directly on the truck. Normally that is done manually by a scaler who measures and examines the timber load to decide the quality, from a platform by which the timber truck is parked.

Slowly, it´s becoming more and more common with remote measuring. In this case the truck is parked and the load is photographed by nine cameras from different angles. The “parking place” is also a scale. The driver registers all other necessary facts about the timber load, such as landing number, buyer, seller, etc. Also, the driver has to write the landing number on the side of the load for the identification of the wood.

The information, weight and photos are sent to a central Biometria office somewhere in Sweden, where a scaler immediately checks if the photos are good enough. When the photos are ok, the driver can unload the truck. Within 48 hours the result of the measuring should be delivered to all parties involved – contractors, buyer and seller.

The truck

As mentioned above, the truck that Christer was driving this day is a Scania R650 New Generation. Truck and trailer together are 24 meters long and 2,6 meters wide. The payload is 42 tons for truck and trailer together, and the total weight is 64 metric tons. The engine is a 650 hp V8 Scania engine. The whole rig has 30 wheels on eight axels.

Here is a film from my visit to Christer Karlssons Åkeri:

Photos and film: Per Jonsson