Vinnova, Sweden’s Innovation Agency, together with the forest industry and researchers, invests 20 million SEK (approx. 2 million EURO) on development of an autonomous planting system, the Autoplant. The project shall improve forest planting with regard to precision, environmental impact and working environment.

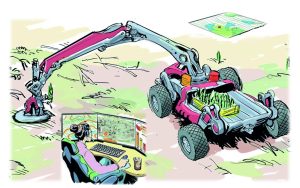

Autonomous planting machine

Autoplant is the second step in a research program that aims to solve societal challenges through collaborative projects that contribute to the sustainability goals in Agenda 2030.

“The forest is an important resource in a biobased society as the raw material from the forest makes the phasing out of fossil products possible. In the meantime, we need the forest for carbon storage, meaning that we need to establish new forests fast after clear cutting. Therefor we wish to develop new, gentle and efficient methods for reforestation. As it is difficult to find labor for manual planting, and machine operators in the forest suffer from vibrations, we believe that an autonomous, small planting machine is the way ahead.” says Linnea Hansson, Project Manager at Skogforsk (Swedish Forestry Research Institute)

Image: Skogforsk

Autoplant addresses a series of challenges that connects to the sustainability goals in Agenda 2030:

- The climate challenge. Autoplant contributes to that new forest is established faster through better planting spots, higher survival rate and more energy efficient machines.

- The environmental challenge. There will be less soil impact as less area is scarified.

- The working environment challenge. Autonomous machines will do the hard job, and no operators have to sit in the machine as in today’s scarifiers.

- The labor– and equality challenge. Autonomous machines, that in the future could be controlled from cities, could attract new groups of labor and make family life easier.

Initiative from the industry

The initiative comes from SCA who wants to increase the survival rate among plants and secure an efficient forest rejuvenation.

“This would also contribute to Sweden’s competitiveness and good reputation for Swedish forest technology,” says Magnus Bergman, responsible for technique and digitalization at SCA Skog.

Bracke Forest, who is a manufacturer of equipment for reforestation, will have a key role in the project.

“This is a good opportunity to develop cutting-edge technology in close cooperation with researchers and users. We have a long history within scarifying and mechanized planting, and we see this project as part of securing our product range for he future”, says Klas-Håkan Ljungberg, CEO at Bracke Forest.

The future is exciting

Has the time finally arrived? We have asked ourselves that before here at NordicWoodJournal.com, why the development of mechanized planting has been so slow. You get the impression that planting is not important enough. It should be, as it secures future forests and sustainable raw materials. There has been no lack of ideas, it´s only that no concept has had real breakthrough … yet. Here are some examples of ideas that we have written about: