Sweden is a small country in northern Europe where forestry has been a key business for almost 200 years. In a series of articles, we will try to describe the Swedish forestry, what it has meant for Sweden and what it has done for forestry in the rest of the World, e.g. when it comes to development of technology. We will also have a look at forestry in the rest of Europe as well.

Let´s start with some basic facts about Sweden

Sweden is a part of both the Nordic Countries and Scandinavia. Apart from Sweden the Nordic countries are Iceland, Norway, Denmark and Finland. Denmark, Norway and Sweden are the three Scandinavian countries.

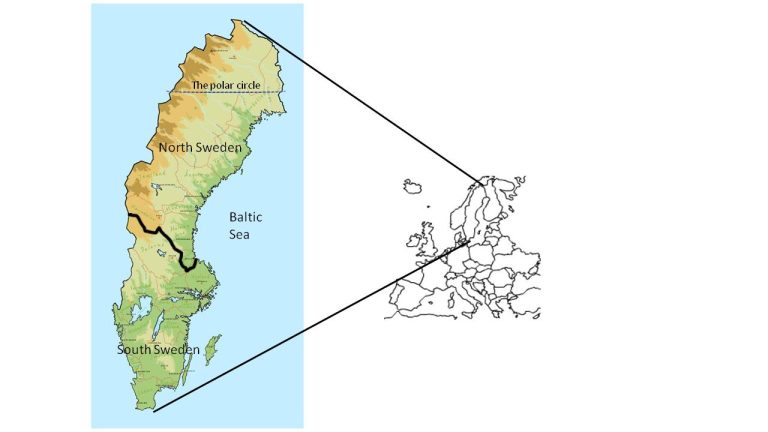

Sweden is 1 600 km (994 miles) long from south to north and is crossed by the polar circle. At the widest spot the width is approximately 500 km (311 miles). The total land area of the country is 40 823 000 hectares (100 875 830 acres). Of these are 23 550 000 hectares (58 193 317 acres) productive forest land. So, 58 % of the country is covered with trees. Although Sweden is a quite small country there are big differences between the north and the south of the country due to differences in climate. Most people live in the south, the large forest industries are in the north, the large forest areas are in the north, but the annual cut is much larger in the south. How can that be?

The average annual growth in the southern parts of Sweden is 6,7 cubic meters (2 366 cubic foot) per hectare and year. In the north the annual growth is 4,2 cubic meters (1 483 cubic foot) per hectare and year. That´s why the 10,5 million hectares in the south produce more wood than the 13 million hectares in the north.

The total cut in Sweden in 2017 was 84 million cubic meters, 22 in the north and 62 in the south.

History

The forest has been important for Sweden for several hundred years, but in the early 19th century it slowly started to become industrial. Tar and coal were among the products that were manufactured in larger scale and traded from the forests. In south Sweden, close to the Norwegian border, sawmills started up to provide Great Britain with sawn timber. By the mid 1800´s the sawmilling people started moving into the north of Sweden. Along the rivers there were “endless” forests that could easily be transported to the east coast (the Baltic Sea) to the sawmills. The logs were simply put in the rivers and floated to the mills. Around 1870 Sweden was the largest exporter of sawn timber in the World. So far mainly the bigger trees were cut.

By the end of the 19th century also the thinner forests gained interest as the pulp mills started to pop up here and there, still mainly in the north. Around 1900 the authorities were afraid that Sweden would run out of wood to the industry and the important export business. As a result, the first national forestry act that forced the industry to reforest the areas that they were cutting clear was founded in 1903. The first law of its kind in the World.

During the 20th century the importance of the forest was growing and to feed the growing forest industries the need for both efficient growing and harvesting technologies was increasing. Axes and blade saws were switched for chain saws, and later on harvesters.

Photo: Per Jonsson

In the 1960´s purpose-built forest machines were popping up, machines that were no adapted agricultural tractors anymore. The Lillnalle, Bruunett and the Blondin were classics.

Photo: Per Jonsson

In the 70´s different types of processors and harvesters showed up. Inventors used trial and error to make them work, and the forest industry helped them by buying the machines although they were not really ready to use. This pushed the development of the machines for forestry, both in Sweden and Finland. There were many competing manufacturers that pushed each other to become better and better. Soon Sweden and Finland were the obvious countries to visit if you were interested in modern forest technology.

The manufacturers are not so many nowadays but the competing and development of harvesters and forwarders still goes on. However, the development of machines for reforestation and precommercial thinning has not had the same pace. Why? The ideas and prototypes for them were also there already in the 70´s.

One reason is the collapse of the iron curtain around 1990. Suddenly there were cheap label available that could plant and do pre commercial thinning in Sweden and other European countries, meaning that the need for machines disappeared. There are signs that this is about to change as conditions and salaries are getting better in many of the old eastern countries. This could be very exciting when it comes to new forest machinery in …

The future

The Swedish forest industry is still very important for the country. The demand for wood- and paper products is still high. There are new ideas about forest machinery popping up but the industry themselves seem not to be so keen on helping as they were in the 70´s. Now it’s up to single inventors to prove that their ideas are good, at their own expense. We have written about this at NordicWoodJournal.com and will write more about it as we find it interesting with people who don´t stop thinking “outside the box”.

Illustration: Harvest Forsttechnik GmbH

Environment

The environmental movement affects the forestry business with different kinds of actions. The problem seems to be that to use renewable materials, such as wood and paper, you have to cut trees. “Only humans cuts down a tree, makes paper of it and write SAVE THE TREES on it”.

In a series of articles, we will describe the forest technology, management methods, people, machines and problems that are actual in the Swedish, and European, forests.

Sources: Swedish University of Agricultural Sciences (SLU), Swedish forest history (skogshistoria.nu), Wikipedia