In April this year it was announced that the two forest machine manufacturers EcoLog and Gremo are merging. In May it was informed that the Gremo forwarders 750, 1050 and 1250 will remain but in EcoLog colors and with EcoLog as a brand name. Now, the first one is underway.

EcoLog 1250F

In the spring EcoLog and Gremo revealed that they were to be merged. A few weeks later EcoLog informed which Gremo models that would live on, but with EcoLog profile – the three forwarders 750, 1050 and the 1250.

The first EcoLog forwarder of “Gremo model” in Ecolog color is now underway in the EcoLog factory in north Sweden. We are talking about an EcoLog 1250F that shortly will be displayed on a demo day in Germany. However, one Gremo forwarder has already been built in the EcoLog factory, but in the original Gremo green color and with components directly from the old Gremo factory in south Sweden.

Assembly and documentation parallelly

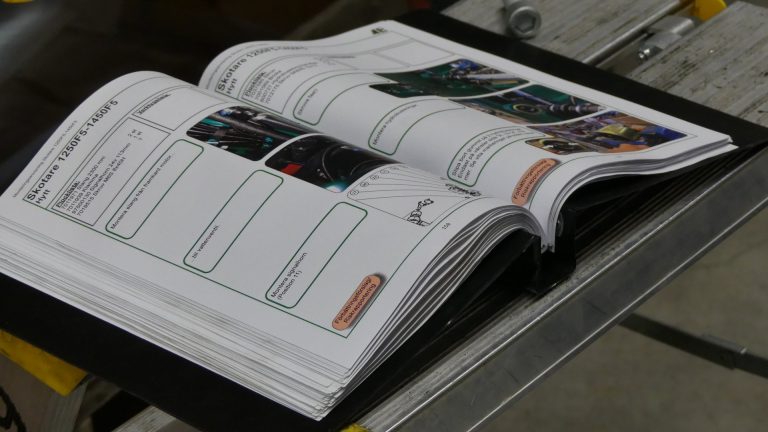

The first Gremo machines that will be built in the EcoLog factory will take a relatively long time. Parallel to the assembly, everything will be documented in the EcoLog system, both CAD drawings and handbooks. Also, the assembly process will be documented.

The documentation is needed to integrate the Gremo articles into the EcoLog spare parts system and to give every article a number. All this takes time and therefor the first machines in this “new” series are built by the most experienced machine builders at EcoLog, in tight cooperation with the administration and aftermarket departments.

The first EcoLog 1250F to Germany

The 1250F that is assembled right now will go to Germany. It is equipped with an Epsilon S110-F tilt crane. The forwarder also has an Active Boogie, which means that the pressure on the front wheel on the boogie is controlled automatically to get maximum traction. A most appreciated function in Germany where they often operate in steep terrain.

The old factory is still in the line

The old Gremo factory in south Sweden will also in the future be important in the manufacturing chain at EcoLog. In the main EcoLog factory, only assembly is made. Welding and similar types of manufacturing will be made elsewhere, partly in the old Gremo factory.

The EcoLog people are somewhat secretive about the future. It seems though as if we can expect changes in the machine ranges, both for machines with EcoLog- and Gremo origin. The ambition is to manage the synergies from the two brands and pick out the best of two Worlds for future machines.

The Cummins engines, however, seem to stay safe in the old Gremo models as the compact measurements suit the forwarders. It allows a small motor hood which gives a good sight from the cabin which is suitable for thinning.

Next machine not far away

During the autumn, more “Gremo machines” will be built. The next one will be an EcoLog 1050F. For the moment delivery times are quite long for the 750, 1050 and 1250 models. A machine that is ordered today can be delivered sometime during the first quarter of next year. This will change when all documentation is finished, and the new range can be integrated into the normal assembly line in the EcoLog factory.

Film and more information

You can read more about the EcoLog range on their homepage here.

And here is a short film from the assembly of the 1250F.