The manufacturer of chain saw protection textile is a pretty anonymous company within forestry but a very important one! I visited Engtex AB in Mullsjö, Sweden and they produce the chain saw protection textile that are used in most saw protection clothes today. They supply Husqvarna, Stihl, Pfanner, Sip, Engebert & Strauss and other manufacturers of protective clothing and they have been developing this type of product since the 70’s.

From the beginning, Engtex in Mullsjö was a textile company that manufactured garment. In the early 70s, they realized that Swedish textile industry will not survive producing clothes. The company started to invest in development of various types of industrial textile. One of these development tracks was saw protection pants and it turned out to be a real success story. Engtex has today a large market dominance in chain saw protection textile but still sees continued strong growth for its products. More about the market further down in the text.

Halved weight – increased strength

Engtex has worked hard on product development over the years. The original polyester fiber has been replaced by other and stronger fiber materials. The weight and thickness of the saw protections have been reduced by half while the protective effect has been improved. Fewer layers and thinner protection also provide better comfort for the user with better air transport and moisture transmission. Everyone who has tested the latest generation of the most expensive pants knows what difference it has compared to the pants from the 80s and 90s. Another difference that is noticed is that the fiber material that provides the best saw protection is also expensive. But put it in relation to what you think your leg or life is worth?

Fiber 15 times stronger than steel

Today, the best saw protection is made of a fiber called Dyneema®. “The world’s strongest fiber” according to the Dutch company that manufactures it. Dyneema is used for super-strong ropes and textile fibers, but also for military protective equipment that must withstand bullets and splinters. Kind of like Kevlar. When I ask Engtex CEO Patrik Johansson why they don’t use Kevlar, he says that it’s “only” five times stronger than steel. Kevlar is also a material that more closely resembles the cellulose fiber in structure. With regard to which fibers the chainsaw is made to cut off, you can understand that it is not a good material for saw chain protection …

The weaving method is the secret

In order for the chainsaw chain to stop when it hits the pants, it must tear off a lot of fibers that follow the chain and get stucked in the sprocket. That is the effect that makes the chain stop. Patrik compares but a common weaving technique. For example, for a bed sheet. There, the threads are woven crosswise with each other and in such a weave “the fabric” locks each thread. It is not possible to pull a single thread out of a sheet.

The weaving technique used in the production of the saw protections is called “warp knitting” and is used in a completely different way. The saw chain protection fabric has a thread structure with two layers of strong Dyneema threads laid perpendicular to each other, but these are held by a third layer which, like “knitting” together the fabric. This means that you can easily pull out each thread no matter in which direction it lies. So, when the saw chain hits the fabric, it easily tears up amounts of super-strong threads that come loose from the fabric and quickly and nicely twist in chain and the sprocket. With a guaranteed stop as a result. Within milliseconds!

Own brand for chain saw protecting textile

Since the actual protective pads in the pants are an “anonymous” product which nevertheless makes a big difference to the pants’ protective performance, Engtex has chosen to protect it’s fabric under the product name “AVERTIC”. Now, some of the clothing manufacturers, such as Stihl in Germany, label their protective clothing with this brand to show the quality of their products.

Three different classes of chain saw protection

We have written about chain saw protection before here at nordicwoodjournal.com. You can read more about how chain saw protection works in this article.

Saw protection capacity in protection pants is tested regularly and by many different institutions. The most well known is the German test and research institution KwF (Kuratorium für waldarbeit & Forsttechnik) who conducts extensive testing of various protection products. Here is a short Stihl test from KwF’s test facility:

There are three different classes of protection for saw protection pants and there are clear guidelines for which requirements are set for each class and how the tests are to be performed. Anyone who does saw protection tests uses a uniform calibration when trimming their test facility. Everyone is using a piece of standardized protection textile. These “calibration pads” are made by Engtex and they consist of a complete saw protection that always has exactly the same caracteristics.

The requirement for the saw protection in each class is that the chain, when it has stopped, should not have damaged the innermost fabric layer in the pants. The different protection classes are:

Class 1, should stand a chain speed of 20 meters/second (65,6 ft/sec)

Class 2, should stand a chain speed of 24 meters/second (78,7 ft/sec)

Class 3, should stand a chain speed of 28 meters/second (91,9 ft/sec)

All tests are done in Europe at a 45 degree angle on the pants leg. In the United States, they are made at a 90 degree angle, cross over the leg.

Six layers

The best of today’s saw protection pants has the protection fabric Avertic Pro or Avertic Pro Lite. The latter weighs only 99 grams/sqm and it takes six layers for protection class 1 or eight layers for protection class 2.

Growing market for chain saw protection

Patrik Johansson at Engtex says that the market outlook looks very good for saw chain protection. There are new markets that have not previously used protective clothing. He mentions several countries in Eastern Europe and Russia as an example. In addition, the use of chainsaws in countries as Germany and others are increasing with an increased need for protecting clothes.

Engtex also sees a large market potential in the US where, according to Patrik, there is a growing market for saw protection clothing. There are many chainsaw users there and among younger people there is a much greater safety awareness than among older generations. Moreover, the manufacturers of protective clothing have succeeded well with their design, which also helps people want to equip themselves with the latest and coolest among chainsaw clothing. To meet demand, Engtex will soon be using a new, more modern and larger production facility.

Manufacturing

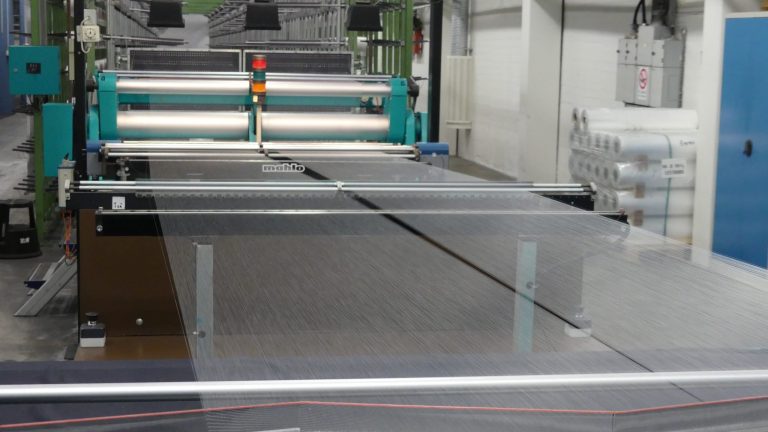

I got a guided tour of the production facility at Engtex and there were many interesting machines involved in weaving the chain saw protection fabric together. The production environment is strictly controlled in terms of temperature and humidity. If the indoor climate becomes wrong, the thin fibers can behave in an undesirable manner. According to Patrik, it may be enough to open an outer door for a short while, in order for a weave to twist.

It all starts with the laying of a warp. This means that the fibers are laid up with the distance they should have in the finished product. In giant racks there are over 1000 large thread spools. The thin fibers are led off the spools in a web towards the collecting reel. The reel winds up the warp at a speed of 60 km/h (37 mph) and there is 10 km (10,000 meters/32 800 ft) of fiber on each spool. In the warp that was set up when I looked there were almost 1200 threads.

When the warp is rolled up and ready, it is then moved over to the machines that make the actual weaving job. Or rather the knitting work. The machines work with needles at a furious pace. With a thin thread, it’s knitting the two layers of Dyneema fibers into a uniform weave which is then rolled up on new rolls. These rolles are then sent to the clothing manufacturers who cut and use the number of protective layers they want in their pants, saw protection boots or protective gloves. So, next time you sit with an undamaged leg and digging a mess of fibers out of the sprocket on your chainsaw, you can give a greatful thought to the product developers at Engtex in Mullsjö!

Here is a video where you can see the manufacturing and som cutting tests: