In a previous article, we wrote about where we find the material wood in our everyday life. It turned out that we have it everywhere around us. But people, the public, don’t understand that it often is wood that surrounds us – wood that comes from the trees in the forest. So, what could be done with wood? As we here in Sweden almost only make pulp, paper, and sawn timber of our woods, my colleague Torbjörn at iSkogen.se had a look at what we could do if we want to or will have to change that. So in this article, you will find his descriptions of engineered wood materials.

Engineered wood and wood components

I recall a carpenter telling me when he restored a city folk’s country house. He suggests using 2 x 4’s which makes the customer wonder, “What is that?” “It’s wood,” he replies. “Does it come from the trees in the forest?” the customer asks. “Yes!”. “In that case, I would prefer to use OSB as it comes from a factory and not from the forest,” the customer demanded. So it says it all.

New challenges for the Swedish forest industry

The EU is evident in their new EU Forest Strategy for 2030 – more wood construction and more sustainable materials. Recent decisions, programs, and directions, such as Green Deal and others, show that wood as a material is a winner in future Europe. This should be good news for a country like Sweden with all the forest and forest industry. But how is Sweden’s ability to face this new future? For example, could engineered wood be an alternative for the Swedish Forest industry?

Only 21 % of the harvested volumes from the Swedish forests become wood products today. The rest becomes pulp for paper and cardboard, but most wood is burned at the pulp mills and the heating plants, something that the EU is not as enthusiastic about the Swedish forest- and energy industries.

The production of wood-based panels and engineered wood is exceptionally modest in Sweden compared to other forestry nations. However, one might think that it would look different and that the possibilities for the Swedish forest industry in the future should be good as more and more shall be built from wood materials according to the EU.

Let’s look at different wood products that should be possible for the Swedish Forest industry to produce – if they are interested.

Wood-based panels

Photo: Unsplash.com

Apart from the typical wood products, lumber from main softwood that we have here in Sweden, there are various other wood-based products. Products that have been processed from wood but are still not finished products, like windows, doors, etc. Especially the construction-, furniture-, interior- and car industries use this kind of wood-based components.

We have listed three such product groups and will describe them: Components of solid wood, wood-based panels, and wood-based building components.

Components of solid wood

Here we find glulam, CLT (Cross Laminated Timber), edge-glued panels, and blockboard. All have that in common that they consist of solid wood pieces that are glued together.

Glulam

It is mainly used in construction as supporting pillars and beams in frames and ceilings. Glulam has an excellent strength/weight ratio and keeps its strength also in the case of fire. It’s manufactured as square beams in various dimensions and could be made in very long lengths. Glulam is also used in advanced and sometimes spectacular truss constructions.

Glulam is used in more significant buildings but also bridges. Thinner dimensions of glulam could be used in smaller buildings for load-bearing structures.

Photo: Svenskttra.se/Johan Ardeboros

In Sweden, glulam is mainly made of spruce wood; Moelven, Holmen, and Setra are producers.

The benefits of glulam, apart from that it is strong, is that it is made of renewable raw material, is recyclable and esthetic according to many, it simply looks good. One downside is that it requires glue that today can’t be produced from renewable sources and that it consumes large volumes of “premium wood.”

You can read more about glulam here.

CLT – Cross Laminated Timber

CLT is a large building element made of boards that are glued together crosswise in layers. The result is large solid wooden boards that could be used as load-bearing walls and floors in houses depending on thickness and strength. The principle is the same as for glulam, but instead of gluing the board layers together in the same direction, the layers are alternating with 90 degrees difference, like plywood made of solid wood.

In the manufacturing process, adaptions are often made for specific building projects. For example, holes for windows and doors are cut out, and canals for installations (cables, pipes, etc.) could be milled out directly according to the building’s drawings. Construction with CTL reminds me of building a gingerbread house where each part comes from the factory ready to be assembled.

Photo: Svenskttra.se/Jens Erneholt

One of the benefits for the building contractor apart from that CLT is made of renewable materials, is that the assembly is fast and requires less transportation as it is much lighter than, e.g., concrete elements. A benefit for the CLT manufacturer is that you can adapt the product for a specific construction project.

Just as for glulam, the downside of CLT is the nonrenewable glue and that it takes a lot of premium wood to produce it. When the wood prices rice like in the past year, CLT becomes expensive. A future possibility could be to use low-quality softwood and hardwoods as raw materials.

CLT is a relatively new product in Sweden, but production increases rapidly. Martinsson, Stora Enso, Setra and Södra are Swedish producers of CLT today. Both the Swedish and the global markets for CLT are expected to grow in the future.

Edge-glued panels

Edge-glued panels are sheet material made from dried mass timber. The panels are produced by gluing together 40 – 45 mm wide woodblocks, usually softwood, although hardwood may also be used. There are various methods, but the most common is to glue the blocks edge to edge to form a sheet of solid wood. It could also be done in layers glued in different directions, like a miniature CLT sheet. It’s also common in edge-glued panels that small blocks are finger-jointed into larger pieces.

Edge-glued panels are available in many wood species. Most of them are used for furniture, joinery, and interior fittings. There are also edge-glued panels for outdoor use, e.g., house panels.

A benefit of edge-glued panels is that tiny bits (waste bits) of wood could be used by finger jointing them into larger blocks. Some might say that a downside is that it consists of solid wood when it could have been made of fiber- or particleboard with veneer on the surfaces. Therefore, particle- and fiberboard could be made of recycled wood and is more environmentally friendly(?).

Photo: Svenskttra.se/Jens Erneholt

There are many manufacturers of edge-glued panels in Sweden, although some are pretty anonymous sub-suppliers to larger companies. There is a vast import of edge-glued panels to Sweden, mainly from eastern Europe and Asia, especially China.

Blockboard

Photo: Ceos.se

Blockboard is an edge-glued panel that is reinforced with a symmetrically bonded veneer or fiberboard. It was more common before in furniture and joinery but is replaced with other wood-based panels today. There are, to our knowledge, no large-scale manufacturers of blockboard in Sweden today. There are, however, several wholesalers who import blockboards of different kinds. It’s mainly used in furniture and interior fittings.

Wood-based panels

Wood-based panels are the most extensive product group within engineered wood. Here you can find materials that have a long history but also good prospects for the future. The products may have been around for a long time, but they are constantly developing. The global market for wood-based panels is gigantic; over 500 million cubic meters per year are produced if you count all types of panels. And the market is growing.

Sweden is a tiny player in this game, but we are a big importer of wood-based panels. In 2020 the import was worth 500 million Euros, according to official statistics. An increase by almost 40 % in 10 years.

Here is a short description of different types of wood-based panels.

Plywood

Plywood consists of several layers of thin veneer that are glued together under pressure. The veneer layer’s fibers are cross-laminated by 90 degrees between the layers. This has given the product the name “cross veneer” in some cases. Plywood is an old product that goes back to the ancient pharaohs in Egypt. It took until the 1800s until it became an industrial product in the US. By the end of the 19th century, the turning of the veneer layers became standard, which meant higher productivity, larger volumes, and lower prices.

The first plywood factory in Sweden (Edsbyn) started in 1912. After that, several plywood factories were built throughout the country. Today is, however, only one left, the Moelven Plywood factory. Otherwise, we import plywood from Finland and the Baltic states.

Plywood is strong and is used within the construction-, furniture- and interior fittings sectors. Other sectors where plywood is frequently used are within the vehicle- and offshore business. Plywood is used as a surface layer on boats, truck bodies, etc. Of the wood-based panels, plywood is the one that is mostly produced in the World.

It’s made in many different qualities and types: Softwood like spruce and pine for construction and plywood of birch wood for interior fittings, public spaces, and the transport sector. Plywood that has been impregnated or surface-treated could be suitable for outdoor use. There is plywood of tropical species or fast-growing Pinus radiata, light plywood made of poplar, etc.

Plywood is manufactured in many countries, of which China, India, the USA, Indonesia, and Russia are the largest producers. In Europe, Finland is the dominating producer with a World market share of 1 %.

Although there is one plywood factory in Sweden, we are net importers. We import (according to FAO) approx. Two hundred thirty-five thousand cubic meters of plywood and exports 30 000 cbm.

A benefit of renewable plywood is that it is light but still firm. The manufacturing process is efficient, and large volumes can be produced. Plywood is an excellent alternative to solid wood as it is thin, light, and still strong, making it suitable for, e.g., roofs.

The glue used is the major downside, just as with the other types of engineered wood, as it is not renewable.

Particleboard

Large-scale production of particleboard started in the ’40s. In Sweden, SCA was the first to create experimental manufacturing in north Sweden, but that plant was closed already in 1954. Officially, the production of particleboard started in Sweden in 1956 in south Sweden.

Particleboard is made of sawdust that is mixed with glue and pressed into the board. Depending on the mix and the pressure, different types of panels could be made. The particleboard quickly became popular due to its dimensional stability and the fact that it was launched when a lot of large construction projects were underway. Factories popped up everywhere in Sweden. One of the two remaining particle board manufacturers, Byggelit, had five factories at the most. Today they have one; IKEAis the other one.

In the ’80s, the particle board was the most common wood-based panel in the World, but plywood has taken over the throne in the last years and is now the most common. Particleboard is, however, still used in the furniture-, interior- and construction sectors.

In Sweden, except for the two producers as mentioned above, the production of particleboard has disappeared. A significant reason for this is a co2 tax that made it more profitable to use sawdust and other rest products from the wood industry as fuel. The particleboard manufacturers were used to getting their raw materials almost for free. Still, as the bioenergy sector could pay for the same material, not much was left for particle board manufacturers.

The introduction of the co2 tax was that Sweden wanted to get rid of the imported oil and replace it with local fuels such as wood pellets. A “wood fiber law” introduced in the ’80s (and disappeared in 1993) that gave the woodworking industry priority to the wood raw material and its byproducts didn’t help. The particleboard manufacturers went bankrupt one by one until today’s two, Byggelit and IKEA, were left.

In other markets with a parallel development of the bioenergy sector, like Austria and Germany, the particleboard industry has managed to survive by developing their products. Customer adaption depends on what it should be used for. Simply put less sawdust and more air in the boards. Or, like many manufacturers offer today, particleboard coated with veneer or laminate as components to the furniture- and interior industry.

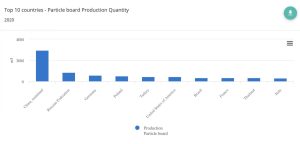

Today, particleboard of recycled wood is available, just like a lightweight board made of poplar, “a fast-growing tree species grown on agricultural land.” The largest producers of particleboard in the World are found in China, Russia, Germany, and Poland.

Source: Fao.org

According to the FAO (Food and Agricultural Organization), Particleboard is the type of board that is most imported to Sweden, totally almost 500 000 m3. The export from Sweden is a little less than 60 000 m3according to the same source.

OSB – Oriented Strand Board

OSB has rapidly become popular in Sweden. It’s a relatively new product; the production started in the USA in the ’60s. OSB, Oriented Strand Board, means that long, thin strips/strands are oriented in different directions in a sheet. The strands usually are around 2,5 x 15 cm (1 – 6 in), mixed with glue, and placed in layers with varying orientations. In each board’s first and last layers, the strands are put in the longitudinal direction with the board. The layers are pressed under heat, and the strands are glued together.

Photo: Unsplash.com

OSB has similar strength as plywood but is much cheaper and lighter. It is a base component in house building in the USA but has also reached Europe. You will find large OSB producers in Europe in Romania, Germany, Poland, and the Czech Republic. However, most production of the OSB is located in the USA, Canada, China, and Russia. Totally 35 million m3 of OSB is produced in the world annually. Sweden has never had any production of OSB, but its use of it is increasing fast. Today we import 150 000 m3 OSB every year.

The benefits of OSB are a good strength/weight ratio and that it could be made from many types of wood raw materials, also from species that are generally not used or have a low value.

MDF board

MDF, Medium Density Fiberboard, has become an increasingly common product, especially furniture and interior fittings. Just like in the manufacturing of particleboard or OSB, MDF is made in a dry process. The difference is that the raw material for MDF has been ground to much smaller particle size, down to fiber size. MDF could be made of many different wood materials if it could be ground to the correct size. The process is, to some extent, like the TMP process (Thermo Mechanical Pulp) of making pulp. Wood chips are heated up and ground between two grinding discs. The fibers are mixed with glue and pressed to hard and homogeneous sheets.

MDF has been produced in Sweden. The production started in the ’90s but was closed in 2012, meaning that all MDF used in Sweden today, more than 230 000 m3, is imported. According to the FAO, the World production of MDF is similar to plywood and particleboard, a little over 100 million m3. China is the largest producer of MDF, followed by Brazil, Turkey, Germany, Thailand, and Poland.

Board – wood fiberboard

Different types of wood fiberboard have been made in Sweden through the years and in large volumes. Well-known brands were Treetex (who used a Swedish patent to release the fibers) and Masonite. The first one was a porous board and the latter a hard one. The wood fiberboards are, indifferent to the previously described boards, produced in a wet process.

The wood material is decomposed to fiber, just like the MDF boards, but mixed with water before it’s placed on a cloth and pressed to sheets. In this process, no glue is needed. The natural “glue,” the lignin, in the wood is enough to make the products stick together. An unmistakable characteristic of wood fiberboard made in a wet process is that they have a pattern after the cloth on the backside.

The American William H Mason got a patent for a method to decompose the wood fibers with vacuum in 1924. That product was called Masonite. The first Swedish factory for Masonite was built in 1929 when P Wikström Jr bought the manufacturing rights and started a production in Sweden where both porous and hard Masonite boards were made.

The Swedish engineer Arne Asplund, working for Mason in the USA, developed another method to decompose wood into fibers in the 1930s. This method is the one described above for the MDF board. Asplund got a patent for his technic in 1934, and several board factories based on his method were built in Sweden. Porous wood fiberboards became in high demand both in Sweden and abroad. The board production was so successful that after World War II, Sweden was the World’s largest producer of wood fiberboard. Today there is no production of wood fiberboard in Sweden. The closest factory is owned by Hunton and is located in Norway.

Photo: Hunton.no

Porous wood fiberboard could be impregnated to become moisture- or fire-resistant. Hardwood fiberboards could be coated for different use. The World’s production of wood fiberboard is modest compared to plywood, particleboard, and MDF. Approx. 7 million m3 annually. The largest producers are the USA, Germany, Poland, and Japan.

Veneer

A veneer is not a sheet material in a sense like other products described in this article. Instead, it’s a thin layer of solid wood that is tightly connected to the board and other sheet materials as it needs some surface to be glued to. The light (0,5 – 3,0 mm) veneer is often the visible part of the furniture- and interior products. Underneath the veneer, you can find either solid wood, MDF, or particleboard.

The veneer could be cut/planed with a knife or turned like when you make plywood (plywood is made of veneer layers glued together to a sheet). Before the veneer is cut or turned, the log is steamed in a steam chamber or hot bath to make the wood more flexible. Exclusive wood species are always cut (planed) with a knife to keep the wood surface’s natural look. This kind of veneer is costly. It could be curly birch, walnut, or other species with beautiful patterns. For example, more common veneers are, e.g., an oak veneer used for furniture and interior fittings made of MDF or particleboard.

There are also veneers that are more artistic designed. The material is processed in several steps: Glued together in patterns and then cut again, for example, to get an uneven structure. The simpler veneer is used as a component in other products. Extensive usage of this is the lower layer of a laminated floor, which is a floor that contains several layers of which one is visible.

There is one manufacturer of veneer in Sweden today, producing veneers of spruce for flooring. Earlier, there were several veneer plants across the country.

The global production of veneer is, according to the FAO, approx. 15 million m3 annually. The largest producers are China, Russia, Vietnam, Indonesia, and Canada. There are no European countries on the top-ten list of veneer producers. Sweden imports 12 000 m3. It may sound minor but bear in mind that if the thickness is 2 mm, 1 m3 will cover a 500 m2 surface.

Wood-based building components – Structural composite lumber – SCL

This is not wood sheet materials, but it’s presented here anyway. It is partly manufactured in the same way and with the same raw material as the sheet materials, especially OSB and plywood.

This is a relatively young product that has its roots in the US. Another name for it is Engineered Wood Products, EWP. The main area of use is within the construction sector. Characteristic for the product category is that it is often customized to be used in standardized building systems.

A critical benefit of SCL/EWP is that it has predicable, very good, and well-defined strength properties. Unlike studs made of solid wood, where the strength is decided by the weakest point, like a knot, etc., the characteristic of the wood is evened out in a glued product that contains several layers. A knot in a veneer layer doesn’t affect the strength of the whole creation.

This attracts the construction sector that needs light and robust components that are predictable and fits into building systems. Many of those products demand only low-grade raw material. They have higher raw material utilization than products made of solid wood—a good point in the climate discussions that we see today.

As with many other engineered wood products, the downside is the glue that is not yet a renewable product.

There is no production other than LVL (see below) in the Nordic countries. The use of this type of product in Europe is very modest but looking at OSB, we know that the market for a specific product can change fast. So, for the Swedes and the other Nordic countries, it might be a good idea to keep an eye on “SCL/EWP.”

LVL- Laminated Veneer Lumber

LVL was developed in the US during the ’70s as smaller building components called “Micro-LAM.” The production took off in the ’80s. LVL is made of veneer layers glued together with all the fibers oriented lengthwise, unlike plywood, where the layers are oriented crosswise. Another difference is that LVL is not made in sheets but more like beams that could be made in very long lengths.

LVL has good and predictable strength characteristics and is used for bearing constructions like trusses, tiers of beams, and frames, mainly indoors. LVL is also used to produce so-called i-joist as upper and lower layers glued onto a bearing component of OSB or fiberboard.

In the Nordic countries, LVL is produced by Metsä Wood in Finland under the brand Kerto and Stora Enso in Finnish Varkaus.

PSL – Parallel Strand Lumber

PSL is made of long strips of veneer, so-called strands, that are glued together to strong beams. The strands could be several meters long, and all are oriented with the fibers lengthwise in the beams. This gives a homogeneous material with very high strength in relation to the weight. PSL is used as bearing components, mainly indoors.

LSL – Laminated Strand Lumber

This is a product that very much looks like LVL but is closely related to OSB. The strands are shorter than in PSL, shorter than 30 cm (1 ft), and lower quality wood, often hardwoods, is used. Unlike PSL, all strands are not placed with the fibers lengthwise, giving components with better strength and form characteristics. It’s mainly used in the construction sector.

Photo from the US.

OSL – Oriented Strand Lumber

It is like LSL but has shorter strands oriented lengthwise and glued together under pressure into different components. Low-quality wood is used, preferably hardwoods like birch, aspen, and poplar. OSL is used in several types of bearing constructions in buildings and furniture.

Photo from the US

Conclusion

Looking at Torbjörn’s presentation of wood-based materials, one might think that Sweden as a nation has several options to utilize its forests in a way that meets the demands of the EU Forest Strategy for 2030. The question is if the industry is interested in that? The pulp- and paper industry in Sweden is powerful and is ruling Swedish forestry.

A huge step is switching from today’s industry into producing the products mentioned in this article. On the other hand, Sweden did have a large board industry before so, why not again? Money!! Is one answer. There is no doubt that Sweden makes money on pulp and paper and most likely wants to continue doing that. But looking at the markets today, it seems it should be possible to make money also on wood-based materials.

This will be interesting to follow.

Sources: FAO, SCB, Wikipedia, and different manufacturers of sheet materials