Many gets their livelihood from the forest. Forest owners, forest contractors, forest industries and more. But do we really utilize the forest as much as we can? Can we do more?

Can we get more from the forest with today’s biomass equipment?

In most forests, there are annoyingly volumes of small trees. Trees that are too small for pulpwood and too expensive to take out of the forest or to just cut down. Here we are not talking about roadsides, powerlines etc. where the trees have to be removed for other reasons than forestry. We are talking about trees that should have been removed in pre-commercial thinning years ago. Trees that now just wait to be thick enough for pulpwood, which will not happen within reasonable time because they are standing too dense.

Photo: Per Jonsson

Abundance of biomass

Theoretically, those trees could be used for biomass producing environmentally sound energy. This is nothing new. It has been discussed for decades. The problem has always been how to get it out from the forest in a cost-efficient way – how to make it profitable for all involved.

A lot of biomass from small trees is used in Sweden and elsewhere today, but the material mainly come from clear cut residues, road- and field sides, or construction sites. For short periods it has been profitable to take out biomass instead of pulpwood from young commercial thinning, but that never lasted for long.

When it comes down to it, supply and demand control the market. A cold winter is good for the bioenergy market, a warm winter is not. High oil prices is good for bioenergy, low prices are not.

Photo: Per Jonsson

Technology for biomass

There is no lack of technology for handling biomass from the forest. Chippers for the purpose has been around since the 70’s, as we wrote about in an article about Allan Bruks a while ago. Around 2005 and some years onward, the market was flooded with logging equipment, such as felling heads and carriers for biomass from the forest.

Many of those products were meant for the private forest owner to mount on a tractor. Some were more professional, like ABAB, Bracke, Narva, Mecanil and some others. Also, Ponsse and John Deere had felling heads for biomass in their ranges back then.

Photo: Per Jonsson

Photo: Per Jonsson

The Smallwood project

To have a closer look at this, a project has been initiated by the Swedish University of Agricultural Sciences together with universities and partners in Finland, Slovenia and Spain. One manufacturer of felling heads for biomass, Bracke Forest AB in Sweden, is also a partner in the project.

The project aims to find more cost-efficient methods to take out thin material from the forest in the four countries. According to Smallwood there is a potential to harvest 20 – 30 million cbm of thin material annually in Sweden and Finland alone if efficient systems for harvesting can be developed.

The areas, Small Diameter Stands (SDS), that have the highest potential to be harvested are thinning, coppice, forest fire prevention cutting and linear areas like road- and field sides. This kind of stands have the potential to support growth of the forest-based bioeconomy in Europe according to Smallwood.

The Smallwood project will develop and bring two Harvesting and Extraction Innovations (HEIs) closer to the market. These are:

- Multi tree harvesting techniques combined with new working methods, and

- Combined harvesting and chipping.

The objective is to increase the sustainable utilization of thin stems through improved management. An effect could be boosting new SMEs and work opportunities in rural areas.

Trials in all four countries

Three trials have been made, one in each involved country except Spain. The Spanish trial had to be postponed because of the outbreak of the Covid-19 pandemic. It´s now being planned for September 2020, but there is a great risk that it will be postponed again.

To make the trials comparable, the same machine and the same operator have been used in all countries. The machine is a Komatsu 901.4 harvester equipped with a Bracke C16 felling head that has been slightly modified with an extra horn above the head to be able to handle longer stems. The machine is for the moment parked in Spain awaiting the pandemic to allow the last trial to start.

Photo: Smallwood.eu

Results from the Swedish trials

The results that are available so far, are the ones from the Swedish trial. Selective thinning and boom corridor thinning in a young dense stand were compared in this trial. In both cases, the same machine, the above-mentioned Komatsu 901.4, was used, with the same felling head and operator.

The Swedish trial stand

Scots Pine dominated stand with Norwegian Spruce, birch and other broad leaves.

Average 5 000 stems per hectar (> 30 mm at DBH, (Diameter at Breast Height)). Variation 2 000 – 9 000 stems/ha.

Average height: 10,2 meters.

Standing volume: 186 cubic meters biomass per hectare (93 tons dry biomass/ha). Estimated with biomass functions.

The results

The results are based on scaled biomass and present an average of the results from selective and boom corridor thinning. The boom corridor method was, however, well 10 % more efficient than the selective thinning in the trial.

Average harvest: 89 cbm solid biomass/ha (44,5 tons dry biomass/ha).

Average productivity: 11,4 cbm solid biomass/G0 hour (5,7 ton dry biomass/ G0 hour).

The operator´s comments

The operator that is following the test machine around Europe, Kjell Törnqvist, has a lot of experience of harvesting thin stems with a Bracke C16 felling head. For many years he operated his own Komatsu 911 with a C16 head. He was also on many occasions hired by Bracke Forest as a demo driver for demonstrations and trade fairs.

Photo: Per Jonsson

“It´s important to have the right base unit”, he says. “A strong crane and good hydraulics make a big difference. My old 911 was a bit stronger which made it slightly quicker, than this 901.”

Another point that he mentions is the length of the stems. In the Swedish and Finnish trials, the length was around 10 meters in average. Here, the C16 head works very well.

“But in Slovenia”, he tells us “the stems were 20 meters high which made it difficult to handle the stems. Here it would have been nice to have feed rollers on the head, like on an ordinary harvester head.”

What about the modification of the C16 head?

To make it easier to handle longer stems an extra horn was mounted above the C16 head that was used for the tests.

“It actually helped, it was easier to handle the long stems with that horn”, Kjell says.

Photo: Smallwood.eu

What will come out of this?

As mentioned early in this article, neither the technology nor the discussion is something new. For some reason, it seems that it´s difficult to reach the efficiency needed to make it break through in a wide range.

It is, however, positive that universities and governments still keep trying. The problem is that the manufacturers of the technology must get the chance to make a profit. Otherwise, they will not join on this trip.

Development of utilization of forest-based biomass

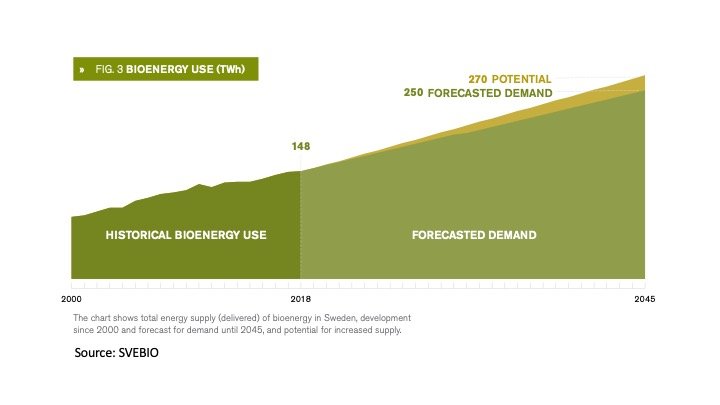

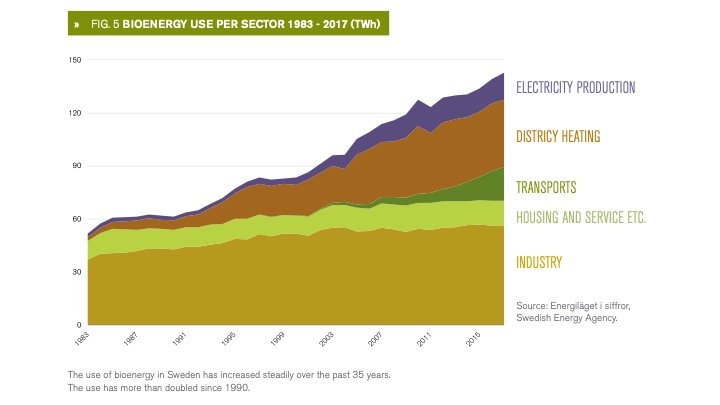

The Swedish Biomass Association, SVEBIO, has produced a roadmap for the development of bioenergy use in Sweden. Here they predict that the use of bioenergy will continue to increase. They also show that the use of bioenergy in Sweden has increased by approx. 3 TWh per year between 1983 and 2017.

You can download and read the SVEBIO roadmap for free here.

Summary

Bioenergy from the forest will continue to grow, especially in forest countries like Sweden, Finland, Slovenia and Spain + many others. The use of fossil fuels has to decrease in order to reach the environmental goals and bioenergy one replacement yo count on.

Sources: Smallwood.eu, SVEBIO

Special thanks to Professor Tomas Nordfjell for sharing the results from the Swedish trials, to operator Kjell Törnqvist for sharing his experience and to Alan Sherrard at SVEBIO/Bioenergy International for sharing statistics and knowledge.