Read the story about how forest owner Anders Hemgren in Stockholm bought a new Usewood Combi Master forest machine. Anders had never operated a forest machine or a crane before. Now he runs his own harvester in his own forest.

Anders works and lives in Stockholm but he has a forest property some 200 km (120 miles) up north in Sweden. As there is a lot of thinning to do, Anders searched for smart ways to get the job done. Without using too big machines. He visited a specialized thinning event (Gallringsdagarna) in Dalarna 2017 where he saw the Usewood machine for the first time and that small machine concept appealed to Anders. When Usewood launched their combi version during 2018, Anders went to Finland and ordered a new machine direct from the manufacturer.

The reason why the Usewood machine concept appealed to Anders was that he could transport it on a trailer after the car between Stockholm and Ockelbo where his forest is located. With the Combi version of Usewood, he has a harvester for the smallest thinning, but a forwarder who is also able to bring out also larger (chainsaw cut) logs as i e storm felled wood.

The new machine, a Usewood Combi Master, was delivered last November (2018) and I booked a date with Anders to shoot some video. When we should meet in Ockelbo early February, there was 70 cm snow so we had to go for a “plan B”. Anders simply hung the machine after the car and went down to a forest-owning friend a little more south in Sweden where the conditions were better. The rumor had also reached Finland so both Jussi-Pekka and Olli Usenius, the people behind Usewood, showed up in the forest.

The Usewood can be moved with a car

Anders told me why he chose Usewood. Most of all for the size. It’s possible to load it on the trailer and pull it with the car (a pic-up truck). But also that it’s built as a combi-version. This is a machine that can be both a harvester and a forwarder. Then he also wanted to have a roll feeding harvester head, as he thinks it looks far too slow with a stroke delimber which is common in this size of machines. The machine that was delivered to Anders was also the first Combi made by Usewood.

Usewoods own crane and two different heads

Usewood’s machines are now available in three different versions: Log Master is the forwarder, Forest Master is a harvester (can also be fitted with a brush cutter) and Combi Master, which is a combi of harvester, forwarder and brush cutter for young stand clearing. The forwarder has a Farma crane but the other two machines have an own designed crane from Usewood.

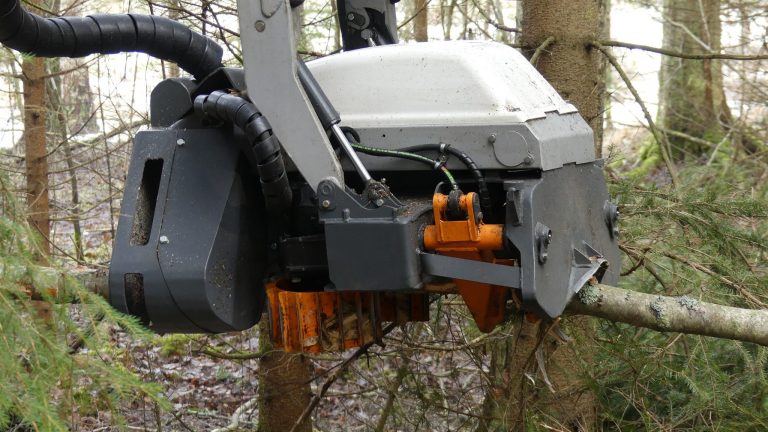

Usewood also manufactures a small, roll-fed harvester head (UW 180S) and a brush cutter head (UW 50). More about the harvester head further down.

To shift from harvester to forwarder is easily done. The head is lowered on a flat surface and then it is only to loosen a pin to the rotator, six hydraulic hoses with quick connections and finally an electric connection. Then it’s just to aim the crane on to the grapple. Put in the pin, connect the hydraulic hoses and then change at the machine computer’s display that there is now a grapple dangling in the crane.

When changing to forwarding, the rear frame is extended by hydraulics with 70 cm extra length and an extension to the rearmost struts is folded out. When the struts are in place, the front gate folds up. It’s folded down during harvesting work for better visibility.

8WD and support legs

All Usewood machines have eight wheels and drives on all eight. There is a hydraulic motor in each bogie and it may appear to be a little sensitive placed between the wheels. The manufacturer claims though, that they have had no problems with the placement. It’s a strong and durable fitting and it’s also well protected between the wheels. Hydraulic support legs, flap down type, are also mounted on the machine and they are needed if you don’t want to roll over the trailer part of the narrow machine. It is only 150 cm (60 in) wide. With the crane at max extension and the 220 kg (485 lb) head, the trailer tilts directly without supporting legs.

Olli Usenius from Usewood showed some driving (can be seen on the video) where you can see that he didn’t use the support legs when he was working straight behind the machine. When working on the side of the machine, he usually just put down one support leg on the same side he worked. Anders told me he always goes safe and put down both legs. He learned the lesson after he had rolled over once. But it was easy to pull the trailer back again with help of the winch and no damage happened.

Without crane experience

When Anders got his Usewood in November, he hadn’t even driven a trailer crane before. Previous crane experiences were equal to zero. Slowly but surely, he is now learning to run a harvester and it sometimes goes really well. One must not think too much, says Anders. You need to get the movements into your “muscle memory”. In addition to the crane skills, many other “achievements” will also come gradually. As for example, to understand that it’s much faster and easier to load and forward the wood if you can sort the tree species and make nice piles with the harvester. Anyway, the pace of production is not the most important for Anders, but more how it looks in the forest afterwards. And if it’s also very fun is no disadvantage. A machine investment of this level probably has to be covered by the account for fun and joy to some extent to be justified.

Harvester for small trees

Although this machine is in many ways a capable thinning harvester, it’s important to be aware of the limitations. The harvester head can’t be compared with those that are, for example, mounted at Vimeks, Terris or Malwas harvesters (type LogMax 928) in capacity and production. Usewood’s unit is powered by the same oil pump that drives the crane and the machine. The feeder rolls requires a lot of power and flow, which makes it tough if the twigs are too thick. It also fails to fell more than 22 cm in diameter, but that can be good enough for thinning in even diameter stands of young forests. In a suitable thinning stand of spruce or pine, it works excellent in small stems (approx. 0.04-0.06 cubic meters/1,4 – 2,1 cubic ft per tree). This heads works also well in the corresponding birch forest. If you compare it with a stroke delimber, Usewood’s head is considerably faster.

Machine no. 76

The machines that have been sold in Sweden have so far been bought by larger forest owners (like Anders), while Usewood has sold machines to professional contractors in the Baltic states that run them full time in thinning. In total, Usewood has manufactured about 80 machines and Anders Combi Master was machine No. 76. According to Usewood’s site, the basic machine costs about 61 000 Euros (US$ 70 000), and then the head, crane extension etc is added. According to the manufacturer, the machine Anders bought costs about 90,000 Euro including everything (US$ 102 000)

You can read more about technical specifications at Usewoods web site

Here is a video from the visit and some pictures